In today’s world, plastic fabrication plays an essential role across numerous industries, from healthcare and retail to automotive and construction. When it comes to creating high-quality, durable plastic products, you need a partner that not only understands your unique requirements but also delivers precision and excellence every time. At Acrylic Art, we specialize in custom plastic fabrication to provide solutions that cater to your specific needs, whether you’re looking for unique displays, prototypes, or specialized components.

Why Choose Acrylic Art for Your Plastic Fabrication Needs

Located in California, Acrylic Art has a long-standing reputation for delivering superior plastic fabrication services. Here’s why businesses trust us for their projects:

Customized Solutions: No two projects are the same, and we take pride in our ability to tailor our services to meet your exact requirements. Our skilled team works closely with you from the initial design phase to the final product, ensuring that every detail is executed with precision.

Expertise and Experience: With years of experience in the plastic fabrication industry, our team has mastered various techniques, including cutting, bending, molding, welding, and assembling different types of plastics. This expertise allows us to handle a diverse range of projects, from intricate designs to large-scale productions.

High-Quality Materials: We source only the finest materials, such as acrylic, polycarbonate, PVC, and more, ensuring that every product we fabricate is of the highest quality. These materials offer durability, versatility, and the visual appeal required for a variety of applications.

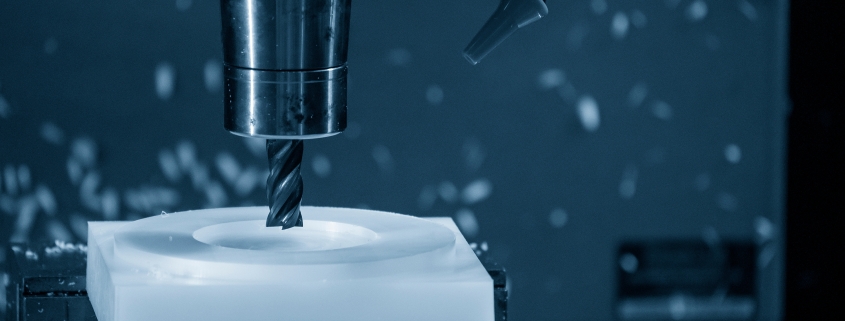

State-of-the-Art Equipment: Our advanced machinery and cutting-edge technology enable us to fabricate plastics with precision and accuracy. We use CNC machining, laser cutting, and thermoforming techniques to bring your designs to life, no matter how complex.

Our Plastic Fabrication Services in California

At Acrylic Art, we offer a wide range of plastic fabrication services to meet the diverse needs of our clients. Here’s how we can help with your next project:

Custom Displays and Retail Fixtures

Retail displays are crucial for attracting customers and showcasing products effectively. We specialize in creating custom plastic displays, cases, and fixtures that not only highlight your products but also align with your brand’s aesthetic. Whether you need countertop displays, freestanding racks, or wall-mounted fixtures, we can design and fabricate pieces that stand out.

Prototyping and Product Development

Bringing a new product to market requires careful planning and testing. Our plastic fabrication services are ideal for prototyping, allowing you to refine designs and test functionality before mass production. With our precise fabrication methods, we can create prototypes that match your specifications and help you identify any improvements needed for the final product.

Industrial Components and Parts

For industries like automotive, aerospace, and manufacturing, high-performance plastic components are essential. We produce a variety of custom plastic parts, including guards, covers, housings, and more, tailored to meet the unique demands of industrial applications. Our robust materials and fabrication techniques ensure that these components withstand harsh conditions and heavy usage.

Signage and Branding

Eye-catching signage is a key element of successful branding. At Acrylic Art, we offer custom plastic signage fabrication services, helping businesses create signs that make a statement. From illuminated signs to engraved plaques and 3D letters, our team works with you to design signage that enhances your brand’s visibility and appeal.

Medical and Laboratory Equipment

In the medical field, precision and hygiene are of utmost importance. Our plastic fabrication services extend to creating custom medical equipment, storage containers, display cases, and lab accessories. We use high-quality, medical-grade plastics that are easy to sterilize and maintain, ensuring they meet the rigorous standards of healthcare environments.

The Benefits of Working with a Plastic Fabrication Company

Partnering with a plastic fabrication company like Acrylic Art offers several benefits:

Design Flexibility: Plastic is a versatile material that can be molded, shaped, and customized to suit various applications. Our fabrication services provide the flexibility to bring even the most intricate designs to life.

Durability and Longevity: The plastics we use are known for their strength, weather resistance, and long lifespan. This makes them an excellent choice for products and components that need to endure constant use or harsh conditions.

Cost-Effective Solutions: Plastic fabrication can be a more affordable option compared to materials like metal or glass, especially when creating complex shapes or large quantities. We work with you to deliver high-quality products within your budget.

Quick Turnaround Times: With our advanced equipment and streamlined processes, we can fabricate products efficiently, helping you meet your deadlines and keep your projects on track.

Ready to start your next project? Contact us today to discuss your ideas and see how we can bring them to life with our expert plastic fabrication services.